The layout

of a gearbox machine tool is influenced by the dimensions and the physical

layout of machine tool. The layout depends to a considerable extent on the

purpose of the machine tool and its type and size.

The layout

of the gearbox can be classified in two ways

1. Gearboxes build in the headstock and

2. Gear boxes in a separate headstock.

1. Gearboxes build in the headstock:

This type of gearboxes are employed in most medium size and heavy machine

tool.

The

Advantages are:

a. A compact spindle size.

b. Space economy.

c. Fewer housing type parts.

d. Cost economy.

e. Higher concentration.

f.

Less

assembly work.

The

Disadvantages are:

a. The possibilty of transmission of the

vibration from the gearbox to the spindle.

b. The spindle head is heated by the

heat generated in the gearbox.

c. Difficulty of employing a flexible

transmission to the spindle.

2. Gear boxes in a separate headstock:

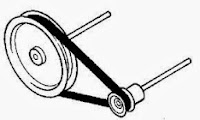

The headstock and the gearbox may be designed as separate units connected

by a belt transmission.

Advantages:

a. Headstock is not heated by the heat

of gearbox.

b. Headstock is not directly affected by

the vibration in the gearbox. And the if the spindle is relived of the belt

tension.

c. The spindle runs smoothly at high

speeds which is important to attain high grade of surface finish and longer

tool life in finishing operations.

Comments

Post a Comment