Boiler

Example: Cochran boiler, Locomotive boiler, Scotch marine boiler, Velcon boiler, simple vertical boiler.

Boiler

Water tube boiler:

In Water tube boilers, the water is contained inside the tubes which are surrounded by flames and hot gases from outside. In water tube boiler feed water flows through the tubes and enters the boiler drum. The circulated water is heated by the combustion gases and converted into steam at the vapor space in the drum. There boilers are selected when the steam demand as well as steam pressure requirements are high as in the care of process cum power/power boiler. The steam capacity of boiler range 4500- 120000kg/h at very high pressure Example: Babcock and Wilcox boiler, Stirling boiler, La Mont boiler, Benson boiler.

Important terms for steam boilers:

1. Boiler shell: It is made up of steel plates bent into cylindrical from reverted or welded together. A boiler shell should have sufficient capacity to contain water and steam.

2. Combustion chamber: It is the space generally below the boiler shell, meant for burning fuel in order to produce steam from the water contained in the shell.

3. Gate: It is the platform in the combustion chamber, upon which fuel is burnt. The gate, generally consist of cast iron bars which are spaced a part so that air can pass through them. The surface are of the gate over which the fire takes place is called gate surface.

4. Furnace: It is the space above the gate and the boiler shell in which the fuel is actually burnt the furnace is also called fire box.

5. Heating surface: It is that part of boiler surface which exposed to the fire.

6. Mountings: There are the fittings which are mounted on the boiler for its proper functioning. A boiler cannot function safely without mountings. Through there are many types of boiler mountings yet the following are important from the subject point view.

a. Water level indicator

b. Pressure gauge

c. Safety valves

d. Stop valve

e. Blow off cock

f. Feed check valve

g. Fusible plug

h. Blow down valve

(a) Water indicator: It is an important fitting which indicate the water level inside the boiler to an observer.

(b) Pressure gauge: A pressure gauge is used to measure the pressure of the steam boiler. It is fixed in front of the steam boiler.

(c) Safety valves: There are the devices attached to the steam chest for preventing explosions due to excessive internal pressure of steam. There are four types of safety valves.

i. Lever safety valve

ii. Dead weight safety valve

iii. High steam and low water safety valve

iv. Spring loaded safety valve

(d) Stop valve: It is the largest valve on the steam boiler. It is used to control the flow of steam from boiler to the main steam pipe.

(e) Blow off cock: It is fitted to the bottom of a boiler drum and consists of a conical plug fitted to the body or casting. Its function is to empty the boiler whenever required and to discharge the mud, scale or sediments which are accumulated at the bottom of the boiler.

(f) Feed check valve: It is a non-return valve fitted to a screwed spindle to regulate the lift. Its function is to regulate the supply water which pumped into the boiler by the feed pump.

(g) Fusible plug: It is fitted to the crown plate of the furnace or the fire. Its object is to put off the fire in the furnace of the boiler when the level of water in the boiler falls to an unsafe limit and thus avoids the implosion which may take place due to overheating of the furnace plate.

(h) Blow down valve: It is fitted to the lower side of the boiler. Its function is to reduce the impurities of the boiler.

7. Accessories: These are the devices which form an integral part of a boiler but are not mounted on it. It may be noted that the accessories help in controlling and running the boiler efficiency.

Though there are many types of accessories yet the following are important from the subject point of view.

a. Feed pump

b. Super heater

c. Economiser

d. Air preheater

(a) Feed pump: A feed pump needed to deliver water to the boiler. The pressure of feed water is 20% more than that in the boiler. The feed pump may be classified as simplex, duplex, triplex pumps according to the number of pump of cylinder.

(b) Super heater: A super heater is an important device of a steam generating unit. Its purpose is to increase the temperature of saturated steam without raising its pressure. It is generally an integral part of a boiler and is placed in the path of hot flue gases from the fluency. The heat given up by these flue gases is used in super heating the steam.

(c) Economiser: An Economiser preheater is used to recover heat from the exhaust flue gases. It is installed between the economizer and chimney. The air required for the purpose of combustion is drawn through the air preheater where its temperature is raised. There is an increase of about 2% in the boiler efficiency for each 35-40% raise in temperature of air.

Figure: Boiler Cycle

Description:

At first, the gas supply from the gas pipe and air supply from the blower with the help of motor. The air and gas mixed by the ratio of 4:1 in the servomotor. Then the mixture of air and gas enter into the tube of the boiler. In the tube there are electrode and a fire glass. The fire produced by the sparking of air gas mixture and electrodes. The fire remains stable by photocell. The voltage produce in the electrode in electrode is 11000 V. There are about 198 tubes and the fire heated the tubes to steam the water. The required steam pass through the pipe and the unexpected steam pass through the chimney. There one pipe line is connected output to the reservoir tank. In reservoir tank water is preheated and there is a preheater and there is a softner tank, which contain normal water, filler water. This tank is used to reduce the hardness of water. The preheated water passes through the feed pump and to boiler. Here some chemicals are mixed with the water. In the furnace oil is used as fuel than there is a connecting pipe from oil tank to servomotor. If the economizer is used then the water is not preheated in the reservoir.

Application:

1. For industrial purpose

2. In power plant

3. To an external combustion engine i.e.: steam engine and turbines.

Flashlight isn't work same way as flashlight work. Just I want to add some information about flashlight below of this boiler article. I have developed a flashlight myself. To develop a flashlight you need reflector, lamp, lens, batteries, switch, contacts, case etc. You can read more here Best Tactical Flashlight Reviews - Top Bright Best flashlight 2017 for details information.

Boiler:

A steam boiler is usually a closed vessel made of steel. Its function

is to transfer the heat produced by the combustion of fuel to water and

ultimately to generate steam.

Types of boiler:

1. Fire tube or smoke tube boiler

2. Water tube boiler

Figure: Boiler

Figure: Boiler

Fire tube boiler:

In fire tube steam boilers, the flames and hot gases, produced by the

combustion of fuel pass through the tubes which are surrounded by water.

Fire tube boilers are generally used for relatively small steam

capacities and low to medium steam pressure. As a guideline fire tube

boilers are completive for steam rates up to 12000kg/h and pressures up

to 18 kg/cm².Fire tube boilers are available for operation with oil, gas

or solid fuel.

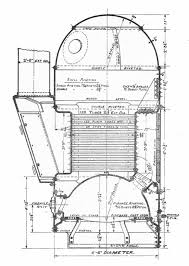

Figure: Vrious parts of boiler

Figure: Vrious parts of boiler

Boiler

Water tube boiler:

In Water tube boilers, the water is contained inside the tubes which are surrounded by flames and hot gases from outside. In water tube boiler feed water flows through the tubes and enters the boiler drum. The circulated water is heated by the combustion gases and converted into steam at the vapor space in the drum. There boilers are selected when the steam demand as well as steam pressure requirements are high as in the care of process cum power/power boiler. The steam capacity of boiler range 4500- 120000kg/h at very high pressure Example: Babcock and Wilcox boiler, Stirling boiler, La Mont boiler, Benson boiler.

Important terms for steam boilers:

1. Boiler shell: It is made up of steel plates bent into cylindrical from reverted or welded together. A boiler shell should have sufficient capacity to contain water and steam.

2. Combustion chamber: It is the space generally below the boiler shell, meant for burning fuel in order to produce steam from the water contained in the shell.

3. Gate: It is the platform in the combustion chamber, upon which fuel is burnt. The gate, generally consist of cast iron bars which are spaced a part so that air can pass through them. The surface are of the gate over which the fire takes place is called gate surface.

4. Furnace: It is the space above the gate and the boiler shell in which the fuel is actually burnt the furnace is also called fire box.

5. Heating surface: It is that part of boiler surface which exposed to the fire.

6. Mountings: There are the fittings which are mounted on the boiler for its proper functioning. A boiler cannot function safely without mountings. Through there are many types of boiler mountings yet the following are important from the subject point view.

a. Water level indicator

b. Pressure gauge

c. Safety valves

d. Stop valve

e. Blow off cock

f. Feed check valve

g. Fusible plug

h. Blow down valve

(a) Water indicator: It is an important fitting which indicate the water level inside the boiler to an observer.

(b) Pressure gauge: A pressure gauge is used to measure the pressure of the steam boiler. It is fixed in front of the steam boiler.

(c) Safety valves: There are the devices attached to the steam chest for preventing explosions due to excessive internal pressure of steam. There are four types of safety valves.

i. Lever safety valve

ii. Dead weight safety valve

iii. High steam and low water safety valve

iv. Spring loaded safety valve

(d) Stop valve: It is the largest valve on the steam boiler. It is used to control the flow of steam from boiler to the main steam pipe.

(e) Blow off cock: It is fitted to the bottom of a boiler drum and consists of a conical plug fitted to the body or casting. Its function is to empty the boiler whenever required and to discharge the mud, scale or sediments which are accumulated at the bottom of the boiler.

(f) Feed check valve: It is a non-return valve fitted to a screwed spindle to regulate the lift. Its function is to regulate the supply water which pumped into the boiler by the feed pump.

(g) Fusible plug: It is fitted to the crown plate of the furnace or the fire. Its object is to put off the fire in the furnace of the boiler when the level of water in the boiler falls to an unsafe limit and thus avoids the implosion which may take place due to overheating of the furnace plate.

(h) Blow down valve: It is fitted to the lower side of the boiler. Its function is to reduce the impurities of the boiler.

7. Accessories: These are the devices which form an integral part of a boiler but are not mounted on it. It may be noted that the accessories help in controlling and running the boiler efficiency.

Though there are many types of accessories yet the following are important from the subject point of view.

a. Feed pump

b. Super heater

c. Economiser

d. Air preheater

(a) Feed pump: A feed pump needed to deliver water to the boiler. The pressure of feed water is 20% more than that in the boiler. The feed pump may be classified as simplex, duplex, triplex pumps according to the number of pump of cylinder.

(b) Super heater: A super heater is an important device of a steam generating unit. Its purpose is to increase the temperature of saturated steam without raising its pressure. It is generally an integral part of a boiler and is placed in the path of hot flue gases from the fluency. The heat given up by these flue gases is used in super heating the steam.

(c) Economiser: An Economiser preheater is used to recover heat from the exhaust flue gases. It is installed between the economizer and chimney. The air required for the purpose of combustion is drawn through the air preheater where its temperature is raised. There is an increase of about 2% in the boiler efficiency for each 35-40% raise in temperature of air.

Figure: Boiler Cycle

Description:

At first, the gas supply from the gas pipe and air supply from the blower with the help of motor. The air and gas mixed by the ratio of 4:1 in the servomotor. Then the mixture of air and gas enter into the tube of the boiler. In the tube there are electrode and a fire glass. The fire produced by the sparking of air gas mixture and electrodes. The fire remains stable by photocell. The voltage produce in the electrode in electrode is 11000 V. There are about 198 tubes and the fire heated the tubes to steam the water. The required steam pass through the pipe and the unexpected steam pass through the chimney. There one pipe line is connected output to the reservoir tank. In reservoir tank water is preheated and there is a preheater and there is a softner tank, which contain normal water, filler water. This tank is used to reduce the hardness of water. The preheated water passes through the feed pump and to boiler. Here some chemicals are mixed with the water. In the furnace oil is used as fuel than there is a connecting pipe from oil tank to servomotor. If the economizer is used then the water is not preheated in the reservoir.

Application:

1. For industrial purpose

2. In power plant

3. To an external combustion engine i.e.: steam engine and turbines.

The important terms provided on this write-up can surely help readers understand the function of boilers more. Thanks much!

ReplyDeletefunctions depends on purposes of boiler and boiler setting place

ReplyDelete