As material

removed from the job, the tool has to advance relative to the job to cut new

areas of the job. This motion is achieved through the feed drive.

Importance

of a Feed Drives are:

1. The drive:

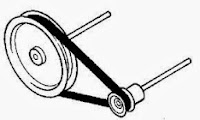

A feed mechanism may be powered by a separate electric motor or from the

spindle drive through kinematic links like gears, chain and belt.

2. Feed engaging devices:

These may be form or friction clutches, sliding gears etc.

3. Feed reversing devices:

While cutting an internal thread the reversing of the feed is usually

required.

4. A safety device for protecting the

feed mechanism against overload. Many design of engine lathes incorporate a

dropping worm to overcome the problem of overloading.

5. A geear train for rapid traverse

movements of carriages, tables etc. driven by a separat e electric motor or by

high speed shafts in the gearbox.

6. The feed gearbox set at the beginning

of the feed.

7. The traversing elements. Its

structural property influences the structure of the feed mechanism to a great

extent.

Comments

Post a Comment